ERW STEEL TUBES

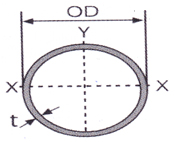

E.R.W. Black tubes are available in the following size range.

Round : 15 mm N.B. to 150 mm N.B.

Square : 20 x 20 mm to 132 x 132 mm

Rectangle: 25 x 15 mm to 200 x 60 mm

Erw steel tubes for ordinary uses in water, gas and air lines conforming to is 1239 (part-1) : 2004

| N.B AND SERIES | OUTSIDE DIAMETER | WALL THICKNESS | NORMAL WEIGHT BLACK TUBES | NORMAL WEIGHT GALVANIZED TUBES | SOCKETS | ||||||||||

| PLAIN END | SCREWED & SOCKETED | PLAIN END | SCREWED & SOCKETED | MIN. OD. | MIN LENGTH | ||||||||||

| MM | MINIMUM | MAXIMUM | MM | SWG | KG/M | M/ TONE | KG/M | M/TONE | KG/M | M/TONE | KG/M | M/TONE | MM | MM | |

| 15 | L | 21.0 | 21.4 | 2.00 | 14 | 0.947 | 1056 | 0.956 | 1046 | 0.947 | 1056 | 0.956 | 1046 | 27.0 | 37.0 |

| M | 21.0 | 21.8 | 2.60 | 12 | 1.21 | 826 | 1.22 | 819 | 1.21 | 826 | 1.22 | 819 | |||

| H | 21.0 | 21.8 | 3.20 | 10 | 1.44 | 694 | 1.45 | 689 | 1.44 | 694 | 1.45 | 689 | |||

| 20 | L | 26.4 | 26.9 | 2.30 | 13 | 1.38 | 724 | 1.39 | 719 | 1.38 | 724 | 1.39 | 719 | 32.5 | 39.0 |

| M | 26.5 | 27.3 | 2.60 | 12 | 1.56 | 641 | 1.57 | 637 | 1.56 | 641 | 1.57 | 637 | |||

| H | 26.5 | 27.3 | 3.20 | 10 | 1.87 | 534 | 1.88 | 532 | 1.87 | 534 | 1.88 | 532 | |||

| 25 | L | 33.2 | 33.8 | 2.60 | 12 | 1.98 | 505 | 2.0 | 500 | 1.98 | 505 | 2.0 | 500 | 39.5 | 46.0 |

| M | 33.3 | 34.2 | 3.20 | 10 | 2.41 | 415 | 2.43 | 411 | 2.41 | 415 | 2.43 | 411 | |||

| H | 33.3 | 34.2 | 4.00 | 8 | 2.93 | 341 | 2.95 | 339 | 2.93 | 341 | 2.95 | 339 | |||

| 32 | L | 41.9 | 42.5 | 2.60 | 12 | 2.54 | 393 | 2.57 | 389 | 2.54 | 393 | 2.57 | 389 | 49.0 | 51.0 |

| M | 42.0 | 42.9 | 3.20 | 10 | 3.10 | 322 | 3.13 | 319 | 3.10 | 322 | 3.13 | 319 | |||

| H | 42.0 | 42.9 | 4.00 | 8 | 3.79 | 264 | 3.82 | 261 | 3.79 | 264 | 3.82 | 261 | |||

| 40 | L | 47.8 | 48.4 | 2.90 | 11 | 3.23 | 309 | 3.27 | 306 | 3.23 | 309 | 3.27 | 306 | 56.0 | 51.0 |

| M | 47.9 | 48.8 | 3.20 | 10 | 3.56 | 281 | 3.60 | 277 | 3.56 | 281 | 3.60 | 277 | |||

| H | 47.9 | 48.8 | 4.00 | 8 | 4.37 | 229 | 4.41 | 226 | 4.37 | 229 | 4.41 | 226 | |||

| 50 | L | 59.6 | 60.2 | 2.90 | 11 | 4.08 | 245 | 4.15 | 241 | 4.08 | 245 | 4.15 | 241 | 68.0 | 60.0 |

| M | 59.7 | 60.8 | 3.60 | 9 | 5.03 | 199 | 5.10 | 196 | 5.03 | 199 | 5.10 | 196 | |||

| H | 59.7 | 60.8 | 4.50 | 7 | 6.19 | 161 | 6.26 | 159 | 6.19 | 161 | 6.26 | 159 | |||

| 65 | L | 75.2 | 76.0 | 3.20 | 10 | 5.71 | 175 | 5.83 | 171 | 5.71 | 175 | 5.83 | 171 | 84.0 | 69.0 |

| M | 75.3 | 76.6 | 3.60 | 9 | 6.42 | 155 | 6.54 | 153 | 6.42 | 155 | 6.54 | 153 | |||

| H | 75.3 | 76.6 | 4.50 | 7 | 7.93 | 126 | 8.05 | 124 | 7.93 | 126 | 8.05 | 124 | |||

| 80 | L | 87.9 | 88.7 | 3.20 | 10 | 6.72 | 149 | 6.89 | 145 | 6.72 | 149 | 6.89 | 145 | 98.0 | 75.0 |

| M | 88.0 | 89.5 | 4.00 | 8 | 8.36 | 119 | 8.53 | 117 | 8.36 | 119 | 8.53 | 117 | |||

| H | 88.0 | 89.5 | 4.80 | 6 | 9.90 | 101 | 10.10 | 99 | 9.90 | 101 | 10.10 | 99 | |||

| 100 | L | 113.0 | 113.9 | 3.60 | 9 | 9.75 | 102 | 10.0 | 100 | 9.75 | 102 | 10.0 | 100 | 124.0 | 87.0 |

| M | 113.1 | 115.0 | 4.50 | 7 | 12.20 | 82 | 12.50 | 80 | 12.20 | 82 | 12.50 | 80 | |||

| H | 113.1 | 115.0 | 5.40 | 5 | 14.50 | 69 | 14.80 | 67 | 14.50 | 69 | 14.80 | 67 | |||

| 125 | M | 138.5 | 140.8 | 4.80 | 6 | 15.90 | 63 | 16.40 | 61 | 15.90 | 63 | 16.40 | 61 | 151.0 | 96.0 |

| H | 138.5 | 140.8 | 5.40 | 5 | 17.9 | 56 | 18.40 | 54 | 17.9 | 56 | 18.40 | 54 | |||

| 150 | M | 163.9 | 166.5 | 4.80 | 6 | 18.90 | 53 | 19.50 | 51 | 18.90 | 53 | 19.50 | 51 | 178.0 | 96.0 |

| H | 163.9 | 166.5 | 5.40 | 5 | 21.3 | 47 | 21.90 | 45 | 21.3 | 47 | 21.9 | 45 | |||

TOLERANCES

| A. Thickness | ||

| 1. Light Tubes | + not limited | |

| - 8% | ||

| 2. Medium and | + not limited | |

| Heavy Tubes | - 10% | |

| B. weight | ||

| 1. Single Tube | + 10% | |

| (Light Series) | - 8% | |

| 2. Single Tubes | + 10% | |

| (Medium and Heavy Series) | - 10% | |

| 3. For quantities per | + 7.5% | |

| Load of 10 Tonnes minimum | - 5% | |

| (Light series) | ||

| 4.For quantities per load | + 7.5% | |

| Of 10 tonnes minimum | - 7.5% | |

| (Medium and Heavy Series) | ||

| C. Length | ||

| Unless otherwise specified 4 to 7 meters. | ||

STEEL TUBES FOR STRUCTURAL PURPOSES CONFORMING TO IS 1161 :1998

Grade Yst 210 , Yst 240, Yst 310

| N.B. and series | OUT SIDE DIAMETER | THICKNESS | NORMAL WEIGHT BLACK TUBES PLAIN END | CALCUATED NORMAL WEIGHT GALVANIZED TUBES PLAIN END | |||

| MM | MM | MM | KG/M | M/TONE | KG/M | M/TONE | |

| 15 | L | 21.3 | 2.0 | 0.947 | 1056 | 1.00 | 1003 |

| M | 2.6 | 1.21 | 826 | 1.26 | 794 | ||

| H | 3.2 | 1.44 | 694 | 1.49 | 671 | ||

| 20 | L | 26.9 | 2.3 | 1.38 | 725 | 1.43 | 699 |

| M | 2.6 | 1.56 | 641 | 1.61 | 621 | ||

| H | 3.2 | 1.87 | 535 | 1.92 | 521 | ||

| 25 | L | 33.7 | 2.6 | 1.98 | 505 | 2.03 | 493 |

| M | 3.2 | 2.41 | 415 | 2.46 | 407 | ||

| H | 4.0 | 2.93 | 341 | 2.98 | 336 | ||

| 32 | L | 42.4 | 2.6 | 2.54 | 394 | 2.62 | 382 |

| M | 3.2 | 3.10 | 323 | 3.18 | 314 | ||

| H | 4.0 | 3.79 | 264 | 3.87 | 258 | ||

| 40 | L | 48.3 | 2.9 | 3.23 | 310 | 3.34 | 299 |

| M | 3.2 | 3.56 | 281 | 3.67 | 272 | ||

| H | 4.0 | 4.37 | 229 | 4.48 | 236 | ||

| 50 | L | 60.3 | 2.9 | 4.08 | 245 | 4.20 | 238 |

| M | 3.6 | 5.03 | 199 | 5.15 | 194 | ||

| H | 4.5 | 6.19 | 162 | 6.31 | 158 | ||

| 65 | L | 76.1 | 3.2 | 5.71 | 175 | 5.86 | 171 |

| M | 3.6 | 6.42 | 156 | 6.57 | 152 | ||

| H | 4.5 | 7.93 | 126 | 8.10 | 123 | ||

| 80 | L | 88.9 | 3.2 | 6.72 | 149 | 6.90 | 145 |

| M | 4.0 | 8.36 | 120 | 8.54 | 117 | ||

| H | 4.8 | 9.90 | 101 | 10.08 | 99 | ||

| 90 | L | 101.6 | 3.6 | 8.70 | 115 | 8.97 | 111 |

| M | 4.0 | 9.63 | 144 | 7.20 | 139 | ||

| H | 4.8 | 11.50 | 87 | 11.77 | 85 | ||

| 100 | L | 114.3 | 3.6 | 9.75 | 103 | 9.97 | 100 |

| M | 4.5 | 12.20 | 82 | 12.42 | 81 | ||

| H | 5.4 | 14.50 | 69 | 14.72 | 68 | ||

| 110 | L | 127.0 | 4.5 | 13.60 | 74 | 13.90 | 72 |

| M | 4.8 | 14.50 | 69 | 14.80 | 68 | ||

| H | 5.4 | 16.20 | 62 | 14.80 | 61 | ||

| 125 | L | 139.7 | 4.5 | 15.00 | 67 | 15.25 | 66 |

| M | 4.8 | 15.90 | 63 | 16.15 | 62 | ||

| H | 5.4 | 17.90 | 56 | 18.15 | 55 | ||

| 135 | L | 152.4 | 4.5 | 16.40 | 61 | 16.78 | 60 |

| M | 4.8 | 17.50 | 57 | 17.88 | 56 | ||

| H | 5.4 | 19.60 | 51 | 19.98 | 55 | ||

| 150 | L | 165.1 | 4.5 | 17.80 | 56 | 18.20 | 55 |

| M | 4.8 | 18.90 | 53 | 19.30 | 52 | ||

| H | 5.4 | 21.30 | 47 | 21.70 | 46 | ||

| 150 | L | 168.3 | 4.5 | 18.2 | 55 | 18.66 | 54 |

| M | 4.8 | 19.4 | 52 | 19.88 | 50 | ||

| H | 5.4 | 21.7 | 46 | 22.24 | 45 | ||

| 6.3 | 25.2 | 40 | 41.00 | 24 | |||

TOLERANCES

| SECTION TYPE | GRADE | OUT SIDE DIMENSION | THICKNESS | SQUARE NESS | CORNER RADIUS | WEIGHT INDIVIDUAL LENGTHS | WEIGHT ON LOT OF 10 MT | CUSTOMIZED OFFER |

| RHS/SHS IS 4923 | Yst- 210 | +-1%with a minimum of +-0.50 mm | +-10% | 90 deg | 3t max | -8%,+10% | +-7.5% | Length-4 M to12 M Thickness-1.4 MM to 8.0 MM |

| Yst- 240 | ||||||||

| Yst- 310 | +-2 deg. | |||||||

| CHS IS-1161 | Yst- 210 | OD upto and incl48.3+0.4/- 0.8 mm;over 48.3+-1% | +no limited | NA | NA | L+10% -8% | L+-5% |  |

| Yst- 240 | -10% | |||||||

| Yst- 310 | M & H+-10% | M & H +-7.5% | ||||||

ERW STEEL TUBES FOR MECHANICAL &GENERAL ENGINEERING PURPOSE IS 3601 :2006

Dimensions and design properties of steel tubes Grade WT 160 &210 &WT 240

| OUTSIDE DIAMETER MM 1 | Thick mm2 | Mass kg/m 3 | Area of cross section m 4 | Moment of inertia cm 5 | MODAL OF SECTION CM 6 | REDIUS OF GYRATION CM 7 |

| 21.3 | 1.8 | 0.866 | 1.10 | 0.53 | 0.50 | 0.69 |

| 2.0 | 0.952 | 1.21 | 0.57 | 0.54 | 0.69 | |

| 2.6 | 1.20 | 1.53 | 0.68 | 0.64 | 0.67 | |

| 3.2 | 1.43 | 1.82 | 0.77 | 0.72 | 0.65 | |

| 26.9 | 1.8 | 1.11 | 1.42 | 1.12 | 0.83 | 0.89 |

| 2.0 | 1.23 | 1.56 | 1.22 | 0.91 | 0.88 | |

| 2.3 | 1.40 | 1.78 | 1.36 | 1.01 | 0.87 | |

| 2.6 | 1.56 | 1.98 | 1.48 | 1.10 | 0.86 | |

| 3.2 | 1.87 | 2.38 | 1.70 | 1.27 | 0.85 | |

| 33.7 | 2.0 | 1.56 | 1.99 | 2.51 | 1.49 | 1.12 |

| 2.3 | 1.78 | 2.27 | 2.81 | 1.67 | 1.11 | |

| 2.6 | 1.99 | 2.54 | 3.09 | 1.84 | 1.10 | |

| 3.2 | 2.41 | 3.07 | 3.60 | 2.14 | 1.08 | |

| 4.0 | 2.93 | 3.73 | 4.19 | 2.49 | 1.06 | |

| 42.4 | 2.3 | 2.27 | 2.90 | 5.85 | 2.76 | 1.42 |

| 2.6 | 2.55 | 3.25 | 6.46 | 3.05 | 1.41 | |

| 3.2 | 3.09 | 3.94 | 7.62 | 3.59 | 1.39 | |

| 3.6 | 3.44 | 4.39 | 8.33 | 3.93 | 1.38 | |

| 4.0 | 3.79 | 4.83 | 8.90 | 4.24 | 1.36 | |

| 48.3 | 2.3 | 2.61 | 3.32 | 8.80 | 3.64 | 1.63 |

| 2.6 | 2.93 | 3.73 | 9.77 | 4.05 | 1.62 | |

| 2.9 | 3.25 | 4.14 | 10.70 | 4.43 | 1.61 | |

| 3.2 | 3.56 | 4.53 | 11.59 | 4.80 | 1.60 | |

| 3.6 | 3.97 | 5.05 | 12.69 | 5.25 | 1.59 | |

| 4.0 | 4.37 | 5.57 | 13.77 | 5.70 | 1.57 | |

| 60.3 | 2.3 | 3.29 | 4.19 | 17.65 | 5.85 | 2.05 |

| 2.6 | 3.70 | 4.71 | 19.64 | 6.51 | 2.04 | |

| 2.9 | 4.11 | 5.23 | 21.59 | 7.16 | 2.03 | |

| 3.2 | 4.51 | 5.74 | 23.47 | 7.78 | 2.02 | |

| 3.6 | 5.03 | 6.41 | 25.87 | 8.58 | 2.01 | |

| 4.0 | 5.55 | 7.07 | 28.15 | 9.34 | 2.00 | |

| 4.5 | 6.19 | 7.89 | 30.90 | 10.20 | 1.98 | |

| 76.1 | 2.6 | 5.24 | 6.00 | 40.57 | 10.66 | 2.60 |

| 2.9 | 5.75 | 6.67 | 44.74 | 11.76 | 2.59 | |

| 3.2 | 6.44 | 7.33 | 48.78 | 12.80 | 2.58 | |

| 3.6 | 7.11 | 8.20 | 54.01 | 14.20 | 2.57 | |

| 4.5 | 7.95 | 10.10 | 65.12 | 17.10 | 2.54 | |

| 5.0 | 8.77 | 11.16 | 70.87 | 18.63 | 2.52 | |

| 88.9 | 2.9 | 6.15 | 7.83 | 72.47 | 16.30 | 3.04 |

| 3.2 | 6.76 | 8.62 | 79.21 | 17.80 | 3.03 | |

| 4.0 | 8.38 | 10.70 | 96.34 | 21.70 | 3.00 | |

| 5.0 | 10.30 | 13.20 | 116.40 | 26.20 | 2.97 | |

| 5.4 | 11.10 | 14.00 | 123.80 | 27.80 | 2.97 | |

| 5.6 | 11.50 | 14.65 | 127.64 | 28.72 | 2.95 | |

| 101.6 | 3.6 | 8.70 | 11.10 | 133.20 | 26.20 | 3.47 |

| 4.0 | 9.63 | 12.30 | 146.20 | 28.80 | 3.45 | |

| 5.0 | 11.90 | 15.20 | 177.50 | 34.90 | 3.42 | |

| 114.3 | 3.2 | 8.77 | 11.16 | 172.33 | 30.15 | 3.93 |

| 3.6 | 9.83 | 12.50 | 192.00 | 33.60 | 3.92 | |

| 4.5 | 12.20 | 15.50 | 234.30 | 41.00 | 3.89 | |

| 5.4 | 14.50 | 18.50 | 274.50 | 48.00 | 3.86 | |

| 6.3 | 16.80 | 21.20 | 315.00 | 55.10 | 3.83 | |

| 139.7 | 3.60 | 12.10 | 15.38 | 356.36 | 51.02 | 4.81 |

| 4.00 | 13.40 | 17.04 | 392.57 | 56.20 | 4.80 | |

| 4.50 | 15.00 | 19.10 | 437.20 | 62.60 | 4.78 | |

| 5.00 | 16.60 | 21.20 | 480.50 | 68.80 | 4.77 | |

| 5.40 | 17.90 | 22.80 | 514.50 | 73.70 | 4.75 | |

| 6.30 | 20.70 | 26.30 | 591.00 | 84.70 | 4.73 | |

| 152.4 | 4.50 | 16.40 | 20.90 | 572.20 | 75.10 | 5.23 |

| 5.00 | 18.20 | 23.20 | 629.50 | 82.60 | 5.21 | |

| 5.40 | 19.60 | 24.90 | 674.50 | 88.50 | 5.20 | |

| 165.1 | 4.50 | 17.80 | 22.70 | 732.60 | 88.70 | 5.68 |

| 5.00 | 19.70 | 25.10 | 806.60 | 97.70 | 5.66 | |

| 5.40 | 21.20 | 27.10 | 864.70 | 105.00 | 5.65 | |

| 6.30 | 24.80 | 31.40 | 992.00 | 120.00 | 5.63 | |

| 168.3 | 4.00 | 16.20 | 20.64 | 696.87 | 82.81 | 5.81 |

| 4.50 | 18.20 | 23.20 | 777.20 | 98.40 | 5.79 | |

| 5.00 | 20.10 | 25.70 | 855.80 | 102.00 | 5.78 | |

| 5.40 | 21.70 | 27.60 | 917.70 | 109.00 | 5.76 | |

| 6.30 | 25.20 | 32.10 | 1053.00 | 125.00 | 5.73 | |

| 7.10 | 28.20 | 35.94 | 1169.66 | 139.00 | 5.70 | |

| 8.00 | 31.60 | 39.70 | 1288.00 | 153.00 | 5.69 |

| A-PHYSICAL PROPERTIES | ||||

| Grade | Y.S. | T.S | % age Elongation (Min.) | |

| As welded (less then Or equal to 33.7 mm OD | As welded (more then Or equal to 33.7 mm OD | |||

| Mpa (min) | Mpa (min) | |||

| WT 160 | 160 | 310 | 15 | 22 |

| WT 210 | 210 | 330 | 12 | 20 |

| WT 240 | 240 | 410 | 10 | 15 |

| WT 310 | 310 | 450 | 6 | 10 |

| B-MANUFACTURING TOLERANCE | ||||

| Over mm | Up to & including mm | Tolerance on outside Diameter mm | ||

| - | 25.4 | +-0.15 | ||

| 25.4 | 51.0 | +-0.18 | ||

| 51.0 | 63.5 | +-0.25 | ||

| 63.5 | 76.1 | +-0.25 | ||

| 76.1 | 88.9 | +-0.31 | ||

| 88.9 | 101.6 | +-0.36 | ||

| 101.6 | 114.3 | +-0.43 | ||

| 114.3 | 152.4 | +-0.58 | ||

| 152.4 | 168.3 | +-0.65 | ||

| 168.3 | - | +-0.75 | ||

| NOTE: The tolerance of thickness excluding the weld shall be +- 10% | ||||

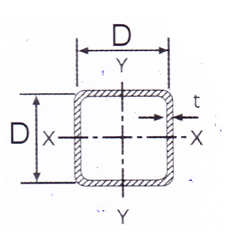

STEEL HOLLOW SECTIONS FOR STRUCTURAL USE (SHS)

Dimensions and depth properties of square hollow sections IS 4923:1997 GRADE Yst 210, Yst 240, Yst 310

| SHS | DEPTH | WIDTH | THICKNESS | WEIGHT | AREA | MOMENT OF | RADIUS OF | ELASTIC | PLASTIC |

| DXD | D | D | OF SECTION | INERTIA | GYRATION | MODULUS | MODULUS | ||

| MM | MM | MM | MM | KG/M | CM 2 | CM 4 | CM | CM 3 | CM 3 |

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

| 20.0x20.0 | 20.0 | 20.0 | 2.0 | 1.15 | 1.33 | 0.58 | 0.68 | 0.61 | 0.61 |

| 20.0 | 20.0 | 2.6 | 1.46 | 2.17 | 0.63 | 0.66 | 0.66 | 0.66 | |

| 25.0x25.0 | 25.0 | 25.0 | 2.6 | 1.69 | 2.16 | 1.72 | 0.89 | 1.38 | 1.76 |

| 25.0 | 25.0 | 3.2 | 1.98 | 2.53 | 1.89 | 0.86 | 1.51 | 1.98 | |

| 32.0x32.0 | 32.0 | 32.0 | 2.6 | 2.26 | 2.88 | 4.02 | 1.18 | 2.51 | 3.11 |

| 32.0 | 32.0 | 3.2 | 2.69 | 3.42 | 4.54 | 1.15 | 2.84 | 3.59 | |

| 32.0 | 32.0 | 4.0 | 3.19 | 4.07 | 5.02 | 1.11 | 3.14 | 4.11 | |

| 40.0x40.0 | 40.0 | 40.0 | 2.6 | 2.92 | 3.72 | 8.45 | 1.51 | 4.22 | 5.12 |

| 40.0 | 40.0 | 3.2 | 3.49 | 4.45 | 9.72 | 1.48 | 4.86 | 6.01 | |

| 40.0 | 40.0 | 3.6 | 3.85 | 4.91 | 10.45 | 1.46 | 5.22 | 6.53 | |

| 40.0 | 40.0 | 4.0 | 4.20 | 5.35 | 11.07 | 1.44 | 5.54 | 7.01 | |

| 50.0x50.0 | 50.0 | 50 | 2.9 | 4.07 | 5.19 | 18.37 | 1.88 | 7.42 | 8.93 |

| 50.0 | 50 | 3.6 | 4.93 | 6.28 | 21.42 | 1.85 | 8.66 | 10.60 | |

| 50.0 | 50 | 4.5 | 5.95 | 7.58 | 24.64 | 1.80 | 9.96 | 12.47 | |

| 60.0x60.0 | 60.0 | 60.0 | 2.6 | 4.55 | 5.8 | 31.33 | 2.33 | 10.44 | 13.35 |

| 60.0 | 60.0 | 3.6 | 6.11 | 7.79 | 40.37 | 2.28 | 13.46 | 16.22 | |

| 60.0 | 60.0 | 4.5 | 7.43 | 9.47 | 47.20 | 2.23 | 15.73 | 19.32 | |

| 72.0x72.0 | 72.0 | 72.0 | 3.2 | 6.71 | 8.54 | 66.32 | 2.79 | 18.42 | 21.80 |

| 72.0 | 72.0 | 4.0 | 8.22 | 10.47 | 79.03 | 2.75 | 21.95 | 26.32 | |

| 72.0 | 72.0 | 4.8 | 9.66 | 12.31 | 90.31 | 2.71 | 25.09 | 30.49 | |

| 80.0x80.0 | 80.0 | 80.0 | 3.2 | 7.51 | 9.57 | 92.71 | 3.11 | 27.29 | 27.92 |

| 80.0 | 80.0 | 4.0 | 9.22 | 11.75 | 111.05 | 3.07 | 27.76 | 33.07 | |

| 80.0 | 80.0 | 4.8 | 11.03 | 13.85 | 127.58 | 3.04 | 31.90 | 38.45 | |

| 91.5x91.5 | 91.5 | 91.5 | 3.6 | 9.67 | 12.32 | 156.49 | 3.56 | 34.21 | 40.24 |

| 91.5 | 91.5 | 4.5 | 11.88 | 15.14 | 187.57 | 3.52 | 41.00 | 48.79 | |

| 91.5 | 91.5 | 5.4 | 14.01 | 17.85 | 215.68 | 3.48 | 47.14 | 56.77 | |

| 100.0x100.0 | 100.0 | 100.0 | 4.0 | 11.73 | 14.95 | 226.35 | 3.89 | 45.27 | 53.30 |

| 100.0 | 100.0 | 5.0 | 14.41 | 18.36 | 271.10 | 3.84 | 54.22 | 64.59 | |

| 100.0 | 100.0 | 6.0 | 16.98 | 21.63 | 311.47 | 3.79 | 62.29 | 75.10 | |

| 113.5x113.5 | 113.5 | 113.5 | 4.5 | 14.99 | 19.10 | 372.88 | 4.42 | 65.71 | 77.33 |

| 113.5 | 113.5 | 4.8 | 15.92 | 20.28 | 393.31 | 4.40 | 69.30 | 81.81 | |

| 113.5 | 113.5 | 5.4 | 17.74 | 22.60 | 432.58 | 4.38 | 76.23 | 90.55 | |

| 113.5 | 113.5 | 6.0 | 19.53 | 24.87 | 469.81 | 4.35 | 82.79 | 98.96 | |

| 132.0x132.0 | 132.0 | 132.0 | 4.8 | 18.71 | 23.83 | 634.39 | 5.16 | 96.12 | 112.69 |

| 132.0 | 132.0 | 5.4 | 20.88 | 26.59 | 700.11 | 5.13 | 106.08 | 125.02 | |

| 132.0 | 132.0 | 6.0 | 23.01 | 29.31 | 762.98 | 5.10 | 115.60 | 136.98 | |

| Apart from above mentioned size, We also manufacture customized and need based requirement. | |||||||||

|

|||||||||

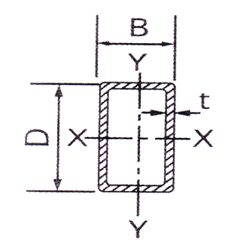

STEEL HOLLOW SECTIONS FOR STRUCTURAL USE (RHS)

Dimensions and depth properties of Rectangular Hollow sections IS 4923:1997 GRADE Yst 210,Yst 240,Yst 310

| RHS | DEPTH | WIDTH | THICKNESS | WEIGHT | AREA | MOMENT OF INERTIA | RADIUS OF GYRATION | ELASTIC MODULUS | PLASTIC MODULUS | ||||||||||||||||||

| DXB | D | D | OF SECTION | ABOUT | ABOUT | ABOUT | ABOUT | ||||||||||||||||||||

| X-X | Y-Y | X-X | Y-Y | X-X | Y-Y | X-X | Y-Y | ||||||||||||||||||||

| MM | MM | MM | MM | KG/M | CM2 | CM4 | CM | CM3 | CM3 | ||||||||||||||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | ||||||||||||||

| 50.0x25.0 | 50 | 25 | 2.9 | 2.98 | 3.80 | 10.93 | 3.60 | 1.70 | 0.97 | 4.37 | 2.88 | 5.72 | 3.48 | ||||||||||||||

| 50 | 25 | 3.2 | 3.24 | 4.13 | 11.63 | 3.80 | 1.68 | 0.95 | 4.65 | 3.04 | 6.14 | 3.73 | |||||||||||||||

| 60.0x40.0 | 60 | 40 | 2.9 | 4.12 | 5.25 | 24.74 | 13.11 | 2.17 | 1.58 | 8.25 | 6.56 | 10.25 | 7.73 | ||||||||||||||

| 66.0x33.0 | 66 | 33 | 2.9 | 4.07 | 5.19 | 27.33 | 9.12 | 2.29 | 1.33 | 8.26 | 5.53 | 10.59 | 6.49 | ||||||||||||||

| 66 | 33 | 3.6 | 4.93 | 6.28 | 31.87 | 10.52 | 2.25 | 1.29 | 9.66 | 6.37 | 12.56 | 7.66 | |||||||||||||||

| 66 | 33 | 4.5 | 5.95 | 7.58 | 36.64 | 11.93 | 2.20 | 1.25 | 11.10 | 7.23 | 14.77 | 8.94 | |||||||||||||||

| 75.0x25.0 | 75 | 25 | 2.9 | 4.12 | 5.25 | 29.82 | 7.72 | 2.38 | 1.21 | 8.52 | 5.14 | 11.07 | 6.04 | ||||||||||||||

| 75 | 25 | 3.2 | 4.50 | 5.73 | 32.04 | 8.24 | 2.37 | 1.20 | 9.15 | 5.49 | 11.98 | 6.51 | |||||||||||||||

| 75 | 25 | 4.0 | 5.45 | 6.95 | 37.23 | 9.42 | 2.31 | 116 | 10.64 | 6.28 | 14.20 | 7.66 | |||||||||||||||

| 80.0x40.0 | 80 | 40 | 2.9 | 5.03 | 6.41 | 50.87 | 17.11 | 2.82 | 1.63 | 12.72 | 8.56 | 16.07 | 9.88 | ||||||||||||||

| 80 | 40 | 3.2 | 5.50 | 7.01 | 54.94 | 18.41 | 2.80 | 1.62 | 13.74 | 9.21 | 17.46 | 10.72 | |||||||||||||||

| 80 | 40 | 4.0 | 6.71 | 8.55 | 64.79 | 21.49 | 2.75 | 1.59 | 16.20 | 10.74 | 20.91 | 12.77 | |||||||||||||||

| 96.0x48.0 | 96 | 48 | 3.2 | 6.71 | 8.54 | 98.61 | 33.28 | 3.40 | 1.97 | 20.54 | 13.87 | 25.85 | 15.91 | ||||||||||||||

| 96 | 48 | 4.0 | 8.22 | 10.47 | 117.54 | 39.32 | 3.50 | 1.94 | 24.49 | 16.30 | 31.21 | 19.14 | |||||||||||||||

| 96 | 48 | 4.8 | 9.66 | 12.31 | 134.35 | 44.55 | 3.30 | 1.90 | 27.99 | 18.56 | 36.13 | 22.08 | |||||||||||||||

| 100.0x50.0 | 100 | 50 | 3.2 | 7.01 | 8.93 | 112.29 | 37.95 | 3.60 | 2.06 | 22.46 | 15.18 | 28.20 | 17.37 | ||||||||||||||

| 100 | 50 | 4.0 | 8.59 | 10.95 | 134.14 | 44.95 | 3.50 | 2.03 | 26.83 | 17.98 | 34.10 | 20.93 | |||||||||||||||

| 122.0x61.0 | 122 | 61 | 3.6 | 9.67 | 12.32 | 232.61 | 78.83 | 4.34 | 2.35 | 38.13 | 25.84 | 47.71 | 29.42 | ||||||||||||||

| 122 | 61 | 4.5 | 11.88 | 15.14 | 278.94 | 93.78 | 4.29 | 2.49 | 45.73 | 30.75 | 57.85 | 35.56 | |||||||||||||||

| 122 | 61 | 5.4 | 14.01 | 17.85 | 320.83 | 107.03 | 4.24 | 2.45 | 52.60 | 35.09 | 67.29 | 41.22 | |||||||||||||||

|

|||||||||||||||||||||||||||

| T.S.(MIN) | Y.S.(MIN) | % ELONGATION | ||||

| GRADE | M | Pa | M | Pa | 25.4 MM | OVER |

| & UNDER | 25.4 MM | |||||

| Yst – 210 | 330 | 210 | 12 | 20 | ||

| Yst – 240 | 410 | 240 | 10 | 15 | ||

| Yst – 310 | 450 | 310 | 8 | 10 | ||

|

||||||